AND HYBRIDIZATION WITH CONCENTRATED SOLAR RADIATION

M. S. Todorovi}, S. Mentus*, O. E}im, Lj. Simi}, F. Kosi, and G. Kold`i}

Laboratory for Thermodynamics and Thermotechnics of the

Division for Energy Efficiency and Renewable Eergy Sources, 11081 Beograd,

Nemanjina 6, *Faculty for Physical Chemistry, Studentski Trg 16, University

of Belgrade

Concentrated Solar Radiation Technologies

Solar technologies are maturing and new opportunities are emerging due to continuing improvements in designs. Concentrated solar radiation (CSR) technologies, combining less-expensive optical components with small area, highly efficient, and somewhat more expensive devices to achieve low cost, in general, are on the threshold of significant development

The stretched membrane concentrator cluster and innovative cavity - heart type high temperature receiver focally positioned present attractive solution for thermal power and photothermal applications. Concentrated solar radiation transmitted by the receiver's cover and adjacent liquid is absorbed by the absorber which has a black nonselective coating and is with its integrated liquid passages immersed directly inside the circulating stream of liquid (4, 5). Highly specularly reflective internal skin of receiver walls reduces the complex of radiative, conductive and convective heat losses and results in a more efficient alternative to highly insulated receiver enclosures (4).

The receiver's instantaneous thermal efficiency is equal to the ratio of heat supplied to the receiver's working fluid and used for the sodium evaporation and its isothermal expansion qkrf versus the incident concentrated solar radiation flux q:

![]() , (1)

, (1)

where qg presents receiver's total heat losses - reflective, radiative, convective and conductive.

The concentrated solar radiation energy flux incident in the receiver's plane is a function of the concentrator field area Ag covered by heliostats Ah = f × Ag = f × CR × Ap , is given as:

q = Ib ×f× CRe ×Ap×r× r (W) (2)

where Ib , CRe , r and r intensity of incident direct solar radiation, effective concentration factor, heliostats field efficiency and its mirror reflectance, respectively.

Steady-state energy flux losses can be expressed as a sum of reflective radiation losses and heat-transfer losses as follows:

![]() (3)

(3)

Radiative losses are given as.

![]() (W) (4)

(W) (4)

Convective qkon and conductive losses qpr are given as:

Thus total heat transfer losses are

![]() (6)

(6)

The influence of the solar radiation concentration factor and the temperature

on receiver's simultaneous short and long wave radiative as well as convective

and conductive heat transfer losses is presented on diagrams in Figure

1. More directly, the kind of efficiency dependence on the solar radiation

concentration factor illustrates the diagram given in the Figure 2.

concentration factor and receivers wall surface temperature.

Alkali Metal Thermoelectric Conversion - AMTEC

The Alkali Metal Thermo-Electric Conversion (AMTEC) (1, 6) a very prospective

(2-5) solution for a high performance power generation became recently

a subject of our interest (4, 5). The key element of an AMTEC device is

the b alumina solid electrolytte (BASE) which

conducts positive sodium ions much better than sodium atoms or electrons

(Figure 3). A sodium pressure difference across a thin BASE sheet drives

sodium ions from the high pressure side to the low pressure side. Thus

positive sodium ions accumulate on the low pressure side, and electrons

collect on the high pressure side, resulting in an electrical potential.

By the appropriate electrode use, this electrical potential can be utilized

and an electrical current can be driven through a load. Liquid sodium in

upper part is maintained at the temperature T2 (900 to 1300K)

by the heat supply from an external heat source (concentrated solar radiation).

The lower part containing condensing sodium vapor and liquid sodium, is

in contact with heat sink at the temperature T1 (400 to 800K).

The thermodynamic cycle equivalent to an the reversible AMTEC process is

given in Figure 4.

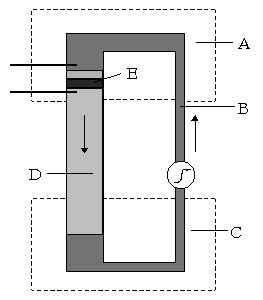

Figure 3 Scheme of alcali-metal-thermo-electric conversion system: A

- Heat source T2, B - Liquid sodium, C - Heat sink, D - Sodium

vapor, E - Beta-alumina solid electrolyte

Thus, BASE presents a mean of converting mechanical energy, related to the established pressure difference, into electrical energy - equivalent to the chemical potential conversion in an electrical potential difference. More accurate study shows that the AMTEC process is more complex interaction of a variety of irreversible transport processes, kinetically governed at the electrode interfaces by the BASE material's specific features. The BASE process described as an isothermal expansion of sodium from pressure p2 to p1 at the temperature T2. Mechanically AMTEC can be described as a simple system without moving parts, except a liquid sodium pump.

Assuming that the sodium vapor can be represented as an ideal gas and employing the Clausius-Clapeyron equation, the instantaneous efficiency of the reversible AMTEC process can be expresses as follows:

(7)

(7)

where is W1 is the maximum work obtained by isothermal expansion

of gas from pressure p2 to p1 at temperature T2,

L2 is the heat of vaporization at T2, q2

is the heat absorbed during isothermal expansion, and by q3

is denoted the enthalpy difference of liquid between T2 and

T1.

Fig. 4. The thermodynamic cycle equivalent to the reversible AMTEC process

and binary AMTEC/SPC.cycle.

Combined Concentrated Solar Radiation Technology - AMTEC and Binary

CSR - AMTEC Cycle

The combined CSR-AMTEC system thermal efficiency can be expressed by

the product of CSR receivers thermal efficiency and the reversible AMTEC

process efficiency (![]() )

by the following equation:

)

by the following equation:

(8)

(8)

The results of performed analysis of the instantaneous thermal efficiency of the thermodynamic model of the combined system CSR - AMTEC (coupled concentrated solar radiation technology CSR and AMTEC process) are presented in Figure 5.

Fig. 5. The dependence of the combined CSR - AMTEC cycle thermal efficiency on the effective solar radiation concentration factor, vapor temperatures and condenser temperature.

Further thermodynamically has been studied binary cycle - combination of AMTEC process and steam power cycle (a scheme of system given in Fig.6).

Fig. 6. Scheme of the hybrid binary CSR - AMTEC/SPC system for the cogeneration

of electrical and thermal energy.

The instantaneous thermal efficiency of the binary CSR - AMTEC/SPC cycle, which has been defined as the combination of the CSR - AMTEC cycle and the steam power cycle can be determined as below:

![]() (9)

(9)

(10)

(10)

where the steam power cycle efficiency, steam power cycle technical work, AMTEC cycle technical work, and the heat rejected by AMTEC are respectively denoted by hRCC, WRCC, qAO.

The results of conducted thermodynamic analysis are very impressive. The obtained values of the relevant thermal efficiencies of CSR - AMTEC and CSR - AMTEC/SPC processes given in Figure 7 are significantly higher than the corresponding values of any conventional power plant in existence today (calculated for the steam power reheat cycle - superheated vapor temperature of 4500C, condensation temperature of 1500C, and with the the SPRC efficiency of 36%). This fact clearly justifies R&D efforts to be increased in the field of relevant fundamental, applied and engineering areas.

Fig. 7. The dependence of the thermal efficiencies of CSR - AMTEC and

CSR - AMTEC/SPC processes on the temperature T2

Hybridization and Cogeneration

For spreading the use of solar energy today is mandatory to have fully dispatchable systems. The best way to do this nowadays is by hybridization with natural gas or oil. In particular both near- and mid-term applications are foreseen for different hybrid solar systems. Such systems, especially those based on concentrated solar radiation conversion technologies are much more competitive and better suited for many diverse applications and emerging international markets than mono-type technologies. Scheme of the hybrid combined. CSR - AMTEC/SPC system given on Figure 6 is ideal for the cogeneration of electrical and thermal energy. For example the binary cycle efficiencies given in Figure 7 are obtained for the steam power cycle condenser temperature of 1500C - the temperature level which can be utilized even as process heat or in district heating systems.

Local Conditions for Technology Development

A review of current local conditions in Yugoslavia confirms that the

technical expertise is appropriate and partly necessary technologies (including

concentrated radiation technologies and PV) are available but financial

situation and economy status present serious barriers and do not favor

promotion of new programs neither in manufacturing and energy engineering

nor investment generally. However demand side menaged decentralized energy

production and integration of NRES in local energy structure shall be seen

as an option which can contribute to improve basic energy supply and living

conditions coupled with the creation of small-scale industry providing

labour and hindering migration to urban centers. In addition to the possible

impact on decentralized energy production development, combined hybrid

solar CSR - AMTEC systems applications include as very prospective generally

autonomous systems (for example electricity for the self powered convective

solar dryers - Figure 8).

Fig. 8. Schemes of convective solar dryers which become self powered and controlled - by the addition of CSR - AMTEC units.

Commercial Implementations and Future R&D Needs

There is a pre-proposal for a two-year program to conduct and evaluate

case studies as possible demonstration sites for hybrid solar-thermal energy

utilization in industrial and commercial sectors in Yugoslavia (a few typical

applications are referred in Table 1). For the program further development

and its effective technical feasibility - reliable and cost-effective solutions

have to be searched encompassing as more as possible accurate investigation

of demand diversity and storage capacities. The program is focused on modular

units from small size engine capacities to, and around 1 MW capacity. .

Table 1.

| Consumer type | Energy Supply Instaled Capacity | Thermal | |

| Electrical

kW |

Thermal

kW |

Electrical | |

| Aromatic oils extraction | 6.69 | 49 | 7.32 |

| Dairy (500-2500 l/8h) | 8.5 - 57.9 | 38.9 - 150 | 4.58 - 2.59 |

| Animal food production (3 t/h) | 82.1 | 30.6 | 0.37 |

| Distillation plant (30-120 m3/h)

wine, 10% Vol. |

24.52 - 67.3 | 198 - 860 | 8.07 - 12.77 |

| Pharmaceutical industry plant | 3455 | 6880 | 1.99 |

As the final conclusions of conducted study otlined can be following needs for furture work:

- Thermodynamic study of innovative combined cycles.

- Fundamental research on different AMTEC systems and relevant materials an structures.

- Engineering investigation,development and standardization of relevant technical systems

- Case studies: loads profiles, storage, cogeneration and hybridization relation dynamics.

- Optimization under various policy/rate scenarios including approach to the dispatch optimization and generalized procedure.

References

- Cole: "Thermoelectric Energy Conversion with Solid Electrolytes" Science, Vol. 221, No 4614, pp. 915-920, 1983.

- Sasakawa, M. Kanzaka, A. Yamada, H Tsukuda, ? Perfomance of the Terrestrial Power Generation Plant Using the Alkali Metal Thrmo-Electric Conversion (AMTEC)? , Proceedings of the 25th Intersociety Conversion Engineering Conference, Vol 3, pp 143-149, 1992.

- Sievers, F.J. Ivanenok and K.T. Hunt: "Alkali Metal Thermal to Electric Conversion", Mech. Engineering, Vol. 117, No 10, pp. 70-76, 1995.

- Todorovic M., F. Kosi: "Ekoenergo-tehnologije - novi sistemi pretvaranja energije za termoenergetiku i termotehniku", KGH, Vol. SMEITS 1996.

- Todorovic M., S. Mentus, O. Ecim and Lj. Simic: "Thermodynamic Analysis of Alkali Metal Thermoelectric Converters of Solar Radiation", Proceedinings of the Fifth International Conference Tesla - III Millennium, pp. IV-87-94., Belgrade, 1996.

Weber: "A Thermoelectric Device Based on Beta-Alumina Solid Electrolyte", Energy Convers. 14, No. 1, pp.1-8, 1974.