IMMOBILIZED CELL TECHNOLOGY (ICT) IN BEER FERMENTATION – A POSSIBILITY FOR ENVIRONMENTALLY SUSTAINABLE AND COST-EFFECTIVE PROCESS

Viktor A. Nedovic1, Ida Leskosek-Cukalovic1, Gordana Vunjak-Novakovic2

1Institute of Food Technology and Biochemistry, Faculty

of Agriculture, University of Belgrade, Nemanjina 6, P.O. Box 127, 11081

Belgrade-Zemun

2Department of Chemical Engineering, MIT, Cambridge,

USA

INTRODUCTION

Whole cell immobilization has been defined as "the physical confinement

or localization of intact cells to a certain defined region of space with

preservation of some desired catalytic activity" (Karel et al., 1985).

Many microorganisms own the capability to adhere to different kinds of

surfaces in nature on which way are in close proximity to nutrients and

easy realize a food supply. Therefore, we can say that these biological

systems in their natural state are immobilizad.

However, many biotechnological processes need to be carried out using

immobilization of biocatalysts. Thereby several different techniques and

support materials have been proposed for the cell immobilization in vitro.

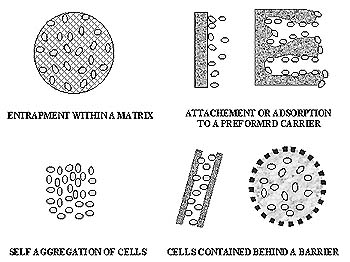

Figure 1 illustrates basic methods for immobilization. These techniques

can be divided into four major groups based on the physical mechanism causing

immobilization: physical entrapment within a porous matrix, attachment

or adsorption to a pre-formed carrier, self agregation by floculation (natural)

or crosslinking agents (artificially induced) and cell contained behind

barrier (Pilkington et al., 1998).

Figure 1 Principal methods of cell immobilization

All of these methods have the same purpose: to retain high cell concentrations

within "a certain defined region of space" such as a bioreactor giving

increased volumetric productivity of a system.

During the last thirty years a numerous different kinds of cell-supporting

materials for immobilization have been developed, such as polymeric matrices

(alginate, agar, gelatin, k-karrageenan, chitosan, pectin, polyacrylamide,

epoxy resin, silica sol), and porous and non-porous preformed support materials

(wood chips, stainless steel, volcanic rock, cotton cloth, porous glass

particles, DEAE cellulose, porous silica, porous ceramics, diatomaceous

earth). The choice of cell-supporting material for any specific application

is related to the following points:

- bioreactor configuration

- high carrier activity

- availability of the carrier in commercial qualities

- low cost of immobilization

- immobilization easy and controllable

- ease of operation scale-up

- excellent mechanical strength during long-time operation

- physiological and environmental safety of the materials used

- low affinity to contaminations

Entrapment in insoluble Ca alginate gel is recognized as a rapid, nontoxic,

inexpensive, versalite and the most often used method for immobilization

of cells (more than 80% of cell immobilization processes are still carried

out using alginate). Alginates make a family of naturally occuring unbranched

binary copolymers, which are formed of D-mannuronic and L-guluronic acids

linked by 1,4-glycosidic bonds. The monomers are arranged in a pattern

of blocks along the chain, with homopolymeric regions (termed M and G blocks)

interspersed with regions of alternating structure-MG blocks (Thu et al.,

1996, 1996). Alginates are differing among themselves by the monomeric

composition and the block structure, and these properties are connected

with the type of algae and the tissue they are isolated from. In the presence

of monovalent cations alginates are forming water solubile salts, but with

polyvalent cations, such as Ca2+, Ba2+ and Sr2+,

they are forming inert polymer network by binding the polyvalent cation

(ussualy Ca2+) to guluronic acid units. This property of alginates

is used for entrapping of living cells in the alginate matrix. The procedure

consists of mixing of cell suspension with Na-alginate solution and dripping

of it into a solution containing divalent cations. This is causing instantaneous

gel spheres formation and cell entrapment into a three dimensional lattice

structure of ionically cross-linked alginate. Since the conditions for

the cells during this procedure are very mild, cells are remaining viable

and catalytic active for a long period of time. There are many examples

of applications of these systems in different fields of industry, medicine

and agriculture.

Immobilization offers many potential advantages over free cell systems,

such as:

- Higher cell densities and cell loads

- Increased volumetric productivity

- Shorter overall reaction times

- Smaller fermenter sizes which may lower capital costs

- The reuse of the same biocatalysts for prolonged period of time due to constant cell regeneration

- A continuous process which may be performed beyond the nominal washout rate

- Improved substrate utilization

- Reduced risk for microbial contamination

- Process design simplified

- Constant product quality

- Improved tolerance or protection of cells from substrate and end-product inhibition.

In technology of food and beverages production, immobilized cell systems are currently used for the production of specific metabolites (Norton, S., and Vuillemard, J.-C., 1994) such as enzymes, amino acids, alcohols, aroma compounds, polysaccharides, pigments, and fermented products such as beer (Masschellein et al., 1994, Nedovic et al., 1996; Kronlof et al., 1996), wine (Divies et al., 1994), cider (Simon et al., 1996; Durieux et al., 1996, Nedovic et al., 1998), vinegar (Mori, 1993), sake (Nunokawa and Hirotsune, 1993), soy sauce (Motai et al., 1993), meat (Norton, S., and Vuillemard, J.-C., 1994), or dairy products (Lacroix et al., 1996; Sodini et al., 1996).

BEER PRODUCTION WITH IMMOBILIZED YEAST CELLS

The production of fermented beverages such as lager-type beer require

a fermentation time of 6-7 days as well as large scale fermentation and

storage capacities. Present trends in immobilized yeast cell technology

nowadays provide the brewing industry with a method of reducing processing

time without sacrificing product quality. By increasing the yeast cell

concentration in the bioreactor vessel, it is possible to accomplish a

faster fermentation and consequently much higher volumetric bioreactor

productivity of beer with significant reduction in fermentation costs.

The earliest applications of immobilized cells to brewing were described

by works of some authors during '70s (Narzzis and Hellich, 1971, Baker

and Kirsop, 1973, White and Portno, 1978). The early packed-bed reactors

consisted of mixture of brewer's yeast and diatomaceous earth forming a

porous biomass bed (Narzzis and Hellich, 1971, Baker and Kirsop, 1973).

Rapidly and efficiently produced beer had the flavour which did not compare

well with that of a similar beer made by conventional fermentation. The

resultant beer had a high concentration of diacetyl, and low of higher

alcohols and esters. Also, the amino acid uptake have been frequently reported

to be low (Pardonova et al., 1982). This and many other studies have found

that amino acid metabolism is obviously critical to beer quality because

the amino acid metabolism is closely linked to production of flavour compounds

such as the vicinal diketones, higher alcohols, organic acids, and sulphur

compounds (Masschelein et al., 1994). The main reason for this unbalanced

metabolic behaviour was altered growth pattern of immobilized cells caused

by mass transfer limitations. In terms of improving amino acid utilisation

as well as beer quality and fermentation efficiency, bulk mixing of the

liquid phase and consequently improved mass transfer is likely to play

an important role.

Thereby in beer brewing with immobilized yeast cells reactor design

has a leading role not only in system selection but also in system efficiency.

Since insufficient mass transfer, i.e. transport of nutrients to yeast

cells, and removal of fermentation by-products from the immobilization

matrix, has been identified as the main factor that causes the unbalanced

flavour profile in beer produced using immobilized yeast packed bed reactors

it was important that extensive care should be taken in assessing and improving

mass transfer in immobilized cell bioreactors. Significant improvement

has been achieved by switching from packed bed to fluidized bed reactors.

Liquid fluidized beds are suitable for support particles that are significantly

more dense than the fermentation medium, because a less dense particle

would be carried upward in these configurations. These systems give much

improved contact between the immobilized yeast and the substrate, which

undoubtedly increases the productivity and permits shorter residence times.

However, mixing may also cause abrasion of the support material, thus affecting

the efficiency of the system

Latest developments in brewing processes with immobilized cells clearly

indicate that by the use of different reactor and system designs, such

as two-stage multi-channel loop reactor system (Andries et al., 1996),

fluidized bed reactor with wort recirculation (Shindo et al., 1994), multi-stage

reactor system (Inoue, 1995) and gas-lift bioreactor system (Nedovic et

al., 1993; Nedovic et al., 1996; Mensour et al., 1996), and a wide range

of beads nature, much better results in a quality of produced beer are

accomplished, than by the use of classic packed bed reactors.

GAS-LIFT SYSTEM

Gas circulating bed reactors can combine the advantages of fluidized

beds, such as high loading of solids and good mass transfer, with the efficient

mixing and controlled liquid flow which are inherent for gas-lift reactors

(Vunjak-Novakovic et al., 1992). The absence of mechanical agitation creates

a relatively low shear environment, which make these reactors ideally suitable

for the application of shear sensitive cells and solid matrix. The solid

phase in external or internal loop bioreactors can be fluidized and kept

in suspension due to circulation of liquid phase and gas bubbles. Low dense

alginate and carrageenan gel particles are typically used in three-phase

gas-lift reactors as carriers of yeast cells in beer fermentations (Nedovic

et al., 1996; Mensour et al., 1996). Since Ca alginate is hydrogel, its

density is very close to that of water and consequently near that of wort.

Mixing requirements for these particles will therefore be relatively low

as compared to heavier matrices such as glass or ceramic beads. The other

important characteristics of gas-lift bioreactors for biochemical processes’

applications are simple construction, low risk of contamination, easy adjustment

and control of the operational parameters and simple capacity enlargement

(Nedovic et al., 1997).

With an interest to produce beer of acceptable quality using immobilized

yeast cells we have designed and studied during the several last years

a three-phase internal loop gas-lift bioreactor used in conjunction with

yeast cells (Saccharomyces cerevisiae) entrapped in small sized Ca-alginate

beds.

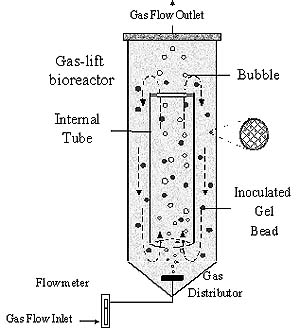

The experimental unit was the internal loop gas-lift bioreactor

with a conical bottom, schematically shown in Figure 2. This reactor consisted

of glass column, gas distributor and glass internal draft tube. The fermenting

wort in the reactor was divided into two distinct zones where only one

of them (internal zone) was spargged by nitrogen. Gas phase was introduced

through a central fritted glass sparger at the conical bottom. The different

gas hold-up in the gassed and ungassed zones resulted in different bulk

densities of the fermenting wort in these regions which caused circulation

and mixing of the wort and beads in the reactor by gas-lift action. The

part of the reactor containing the gas-wort-beads upflow is the riser and

the region containing wort and beads downflow is known as the downcomer.

Solid phase was fluidized alginate particles with immobilized yeast cells,

produced by a droplet generator (FTM, Belgrade), and gellated in calcium

chloride (60 min).

Series of fermentations of hopped wort were carried out in this

bioreactor with the same immobilized cell load.

Figure 2 Schematic presentation of the experimental gas-lift biorector

Main results:

· Primary beer fermentation, which takes 6-7 days in traditional

brewing, was drastically shortened to only about 16 hours.

· Obtained results also showed insignificant differences in

chemical composition and sensory characteristics between beers obtained

with immobilized cells and conventionally produced beers. The concentrations

of higher alcohols and esters were at the same level as those obtained

by the fermentation with suspended cell.

· During the 3-5 months period the same immobilized cell load

of unchanged viability and activity was utilized.

· Within the range of superficial gas velocity between 0.03

and 0.2 cm/s fermentation efficiency showed increasing trend and after

that further increasing in superficial gas velocity little bit changed

the fermentation efficiency.

· Superfficial gas velocity was also the main parameter for

amino-acid nitrogen uptake during the fermentation. The increase of superficial

gas velocity leads to the increase of amino acid consumption. The final

amino-acid concentration was similar to those obtained during the conventional

brewing, and even lower than that.

· By comparing the maximum obtained value of fermentation rate

in the bioreactor with values obtained in packed bed and fluidized bed

reactors one can conclude that internal loop gas-lift bioreactor is much

more efficient among similar systems. It can be explained by liquid mixing

characteristics of the bioreactor, i.e. excellent liquid-solid and gas-liquid

mass transfer within the system, with a balanced flavour profile of finished

product, as a consequence.

INDUSTRIAL SCALE APPLICATION AND ECONOMICAL AND ENVIRONMENTAL ASPECTS

Above all previously mentioned facts there are also several very

significant economical and environmental reasons confirmed through practice

that clearly indicate advantages of the immobilized yeast cell technology

introduction in the industrial beer processing.

- Proposed immobilized cell technology is very simple for introduction

in beer processing. Compact continuously operated processes will increase

flexibility in production planning, and production losses will be smaller.

- Initial savings could be gained by reduction in investment costs

(reduced number and size of the fermentors as well as minimal space requirements),

while further savings could be gained in reduced operating costs.

- There is great variety of different yeast carriers. Some of them

are easily reusable and can have a lifetime of more than 10 years.

- The utilization of yeast carriers leads furthermore to the reduction

of kieselguhr consumption in filtration, which makes handling easier and

cheaper.

- Application of immobilized cell technology will decrease environmental

load, because immobilized yeast reduce waste yeast load, as new biomass

is not produced in conventional quantities. Furthermore, reduced product

losses, reduced water consumption for planning purposes and smaller cleaning

chemicals consumption also have positive environmental effects.

LITERATURE

1. Andries, M., van Beveren, P.C., Goffin, O., Masschelein, C.A. Eur.

Brew. Conv., Monograph XXIV, 134-144, 1996

2. Baker, D.A., and Kirsop, B.H., J. Inst. Brew. 79, 487-494, 1973

3. Divies, C., Cashon, R., Cavin, J.-F., and Prevost, H., Critical

Reviews in Biotechnology 14(2), 135-153, 1994

4. Durieux, A., Garre, V., Mukamana, J., Jourdain, J.-M., Silva, D.,

Plaisant, A.-M., Defroyennes, J.-P., Foroni, G., and Simon, J.-P., Progress

in Biotechnology 11, Immobilized Cells: Basics and Applications, Wijffels,

R.H., Buitelaar, R.M., Bucke, C., Tramper, J., eds., Elsevier Science B.V.,

679-687, 1996

5. Inoue, T., Eur. Brew. Conv., Proceedings of the 25th Congress, Brussels,

25-36, 1995

6. Karel, S.F., Libicki, S.B., and Robertson, C.R., Chemical Engineering

Science 40, 1321-1354, 1985

7. Kronlof, J., Linko, M., and Pajunen, E., EBC Monograph XXIV, Symposium

on Immobilized Yeast Applications in the Brewing Industry, ESPOO, 118-124,

1996

8. Lacroix, C., Sodini, I., and Corrieu, G., Progress in Biotechnology

11, Immobilized Cells: Basics and Applications, Wijffels, R.H., Buitelaar,

R.M., Bucke, C., Tramper, J., eds., Elsevier Science B.V., 600-608, 1996

9. Masschellein, C.A., Ryder, D.S., and Simon, J.-P., Critical Reviews

in Biotechnology 14(2), 155-177, 1994

10. Mensour, N., Margaaritis, A., Briens, C.L., Pelkington, H., Russell,

I., Eur. Brew. Conv., Monograph XXIV, 125-132, 1996

11. Mori, A., Industrial Application of Immobilized Biocatalysts, Tanaka,

A., Tetsuya, T., Kobayashi, T., eds., Marcel Dekker, Inc., 291-315, 1993

12. Motai, H., Hamada, T., Fukushima, Y., Industrial Application of

Immobilized Biocatalysts, Tanaka, A., Tetsuya, T., Kobayashi, T., eds.,

Marcel Dekker, Inc., 315-337, 1993

13. Narzzis, L., and Hellich, P., Brauwelt 111, 1491-1500, 1971

14. Nedovic, V., Obradovic, B., Leskosek-Cukalovic, I., Vunjak-Novakovic,

G., Hem. Ind. 47 (11-12), 168-172, 1993

15. Nedovic, V.A., Leskosek-Cukalovic, I., and Vunjak-Novakovic, G.,

Institute of Brewing, Proceedings of the Twenty Fourth Convention, J. Harvey,

ed., Winetitles, Adelaide, 245, 1996

16. Nedovic,V., Pe{i}, R., Lesko{ek-^ukalovi}, I., Laketi}, D., Vunjak-Novakovi},

G., II European Conference on FLUIDIZATION, M. Olazar and M.J.San Jose,

eds., Univ. Basque Country Press Service, 627-635, 1997

17. Nedovic, V., Durieux, A., van Nedervelde, L., Rosseels, P., Vandegans,

J., Plaisant, A-M., Simon, J-P., Proceedings of the EC Symposium "Yeast

as a Cell Factory", P. Osseweijer and J.P. van Dijken, eds., Vlaardingen,

The Netherlands, 188-190, 1998

18. Norton, S., and Vuillemard, J.-C., Critical Reviews in Biotechnology

14(2), 193-224, 1994

19. Nunokawa, Y., Hirotsune, M., Industrial Application of Immobilized

Biocatalysts, Tanaka, A., Tetsuya, T., Kobayashi, T., eds., Marcel Dekker,

Inc., 235-255, 1993

20. Pardonova, B., Polednikova, M., Sedova, H., Kahler, M., Ludvik,

J., Brauwissenschaft 35, 254-258, 1982

21. Pilkington, P.H., Margaritis, A., Mensour, N.A., Russell, I., J.

Inst. Brew. 104, 19-31, 1998

22. Shindo, S., Sahara, S., Watanabe, N., Koshino, S., Institute of

Brewing, Proceedings of the 23rd Convention, Sydney, 109-113, 1994

23. Simon, J.-P., Durieux, A., Pinnel, V., Garre, V., Vandegans, J.,

Rosseels, P., Godan, N., Plaisant, A.-M., Defroyennes, J.-P., and Foroni,

G., Progress in Biotechnology 11, Immobilized Cells: Basics and Applications,

Wijffels, R.H., Buitelaar, R.M., Bucke, C., Tramper, J., eds., Elsevier

Science B.V., 615-622, 1996

24. Sodini, I., Corrieu, G., andLacroix, C., Progress in Biotechnology

11, Immobilized Cells: Basics and Applications, Wijffels, R.H., Buitelaar,

R.M., Bucke, C., Tramper, J., eds., Elsevier Science B.V., 687-695, 1996

25. Thu, B., Smidsrod, O., Skjak-Braek, G. Progress in Biotechnology

11, Immobilized Cells: Basics and Applications, Wijffels, R.H., Buitelaar,

R.M., Bucke, C., Tramper, J., eds., Elsevier Science B.V., 19-31, 1996

26. Vunjak-Novakovic, G., Jovanovic, G., Kundakovic, Lj., Obradovic,

B., Chem. Eng. Sci. 47, 3451-3458, 1992

27. White, F.H., and Portno, A.D., J. Inst. Brew 84, 228-230, 1978

Viktor

A. Nedovic

Viktor

A. Nedovic

CURRICULUM VITAE

B.Sc. in Food Technology and Biochemistry, Faculty of Agriculture, University of Belgrade.

M.Sc. in Biochemical Engineering, Faculty of Technology, University of Belgrade (Thesis title: Kinetics of Beer Fermentation with Immobilized Yeast Cells in an Internal Loop Air-Lift Bioreactor).

Teaching Assistant for the subject: Brewing and Malting Technology, Institute of Food Technology and Biochemistry, Faculty of Agriculture, University of Belgrade, 1990 to present. Research Associate on several projects in different fields of biotechnology at Dept. of Chem. Engineering and at Inst. of Food Technology and Biochemistry, University of Belgrade, 1990 to present. Visiting Research Associate, Institute Meurice, Dept. of Biotechnology, Campus CERIA, Brussels, Belgium, 1997/1998.

Published and presented over 60 scientific and technical papers in International and Yugoslav Journals and Conferences. Has been invited as a plenary lecturer to two international conferences. Published one monograph. His major research fields are immobilized cell systems, kinetic of biochemical reactions, bioreactor design, beer fermentation, cider fermentation, continuous processes.

Awarded by: The Foundation for young scientists and artists (1990-92), European Commission (EC) - Grant for 1997, Federation of European Microbiological Societies (FEMS) - Fellowship for 1997, EC and FEMS - Grant for 1998, European Congress of Biotechnology - Grant for 1999, Bioencapsulation Research Group - Award for 1999.

A member of Yugoslav Society for Microbiology and Bioencapsulation Research Group (BRG).

Contact address: Institute of Food Technology and Biochemistry, Faculty of Agriculture, University of Belgrade

Nemanjina 6, P.O. Box 127

11081 Belgrade-Zemun, Yugoslavia

Telephone: 381 11 199 711

Fax number: 381 11 193 659 or 199 711

E-mail: vnedovic@eunet.yu

Ida

Leskosek-Cukalovic

Ida

Leskosek-Cukalovic

SHORT CURRICULUM VITAE

Ida Leskosek-Cukalovi} B.Sc. Engineering - University of Belgrade, Faculty

of Technology and Metallurgy, Belgrade

Ph. D. Biotechnological Science, Faculty of Agriculture, Belgrade

Currently: Associated Professor of Brewing Technology, Faculty of Agriculture,

University of Belgrade

Specialization: Heriot Watt University, Edinburgh, UK

A member of the Institute of Brewing, UK. A member of the Organizing

Committee of the II and III Yugoslav Conference on Food Technology.

A member of the Organizing Committee and invited speaker for the Symposium

on Yugoslav Brewing Industry. A member of the Organizing Committee and

invited speaker for the Symposium on Yugoslav Fermentation Industry. Founder

and head of the Laboratory for Brewing at the University of Belgrade, performing

studies in the field of beer science, alcoholfree beer production, membrane

separation technique, yeast immobilization. Member of several Yugoslav

and international multidisciplinary projects performed by joint efforts

University / National Laboratories / Industry, 1979 - 1999. Published and

presented over 80 scientific and technical papers. Has been teaching undergraduate

and graduate level courses in Brewing Science.

Office address: Institute of Food Technology and Biochemistry

Faculty of Agriculture, University of Belgrade

11080 Beograd-Zemun, Nemanjina 6

Phone: (381-11) 615-315/ ext.353

E-mail: i.les@Eunet.YU