Allotropes of carbon

From Wikipedia, the free encyclopedia

Eight allotropes of carbon: a) Diamond, b) Graphite, c) Lonsdaleite,

d) C60 (Buckminsterfullerene or buckyball),

e) C540, f) C70, g) Amorphous

carbon, and h) single-walled carbon

nanotube or buckytube.

This is

a list of the allotropes of carbon.

Contents

4 Buckminsterfullerenes

(4.1 Buckyballs ; 4.2 Carbon nanotubes ;

4.3 Carbon nanobuds) 8 Lonsdaleite (hexagonal diamond)

|

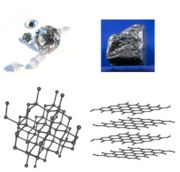

Diamond

Diamond is one of the best known allotropes of

carbon, whose hardness and high dispersion of light make it useful for

industrial applications and jewelry. Diamond is the hardest known natural mineral, which

makes it an excellent abrasive and makes it hold polish and luster extremely

well. No known naturally occurring substance can scratch, let alone cut, a

diamond.

The market for industrial-grade diamonds operates much differently from its

gem-grade counterpart. Industrial diamonds are valued mostly for their hardness

and heat conductivity, making many of the gemological

characteristics of diamond, including clarity and color, mostly irrelevant.

This helps explain why 80% of mined diamonds (equal to about 100 million carats

or 20,000 kg annually), unsuitable for use as gemstones and known as bort, are destined

for industrial use. In addition to mined diamonds, synthetic diamonds found

industrial applications almost immediately after their invention in the 1950s;

another 400 million carats (80,000 kg) of synthetic diamonds are produced

annually for industrial use—nearly four times the mass of natural diamonds

mined over the same period.

The dominant industrial use of diamond is in cutting, drilling (drill

bits), grinding (diamond edged cutters), and polishing. Most uses of diamonds

in these technologies do not require large diamonds; in fact, most diamonds

that are gem-quality can find an industrial use. Diamonds are embedded in drill

tips or saw blades, or ground into a powder for use in grinding and polishing

applications. Specialized applications include use in laboratories as

containment for high pressure experiments (see diamond

anvil), high-performance bearings, and limited use in specialized windows.

With the continuing advances being made in the production of synthetic

diamond, future applications are beginning to become feasible. Garnering much

excitement is the possible use of diamond as a semiconductor

suitable to build microchips from, or the use of diamond as a heat sink

in electronics.

Significant research efforts in Japan, Europe, and the United

States are under way to capitalize on the potential offered by diamond's

unique material properties, combined with increased quality and quantity of

supply starting to become available from synthetic diamond manufacturers.

Each carbon atom in a diamond is covalently bonded to four other carbons in

a tetrahedron. These tetrahedrons together form a 3-dimensional network of

puckered six-membered rings of atoms. This stable network of covalent

bonds and the three dimensional arrangement of bonds is the reason that

diamond is so strong.

Graphite

Graphite (named by Abraham Gottlob Werner in 1789, from the Greek

γράφειν: "to draw/write", for its

use in pencils) is one of the most common allotropes of carbon. Unlike diamond,

graphite is an electrical conductor, and can be used, for instance, as the

material in the electrodes of an electrical arc lamp. Graphite holds the

distinction of being the most stable form of carbon under standard conditions. Therefore, it is used in

thermochemistry as the standard state for defining the heat of formation of carbon

compounds.

Graphite is able to conduct electricity, due to delocalization

of the pi bond

electrons

above and below the planes of the carbon atoms. These electrons are free to

move, so are able to conduct electricity. However, the electricity is only

conducted along the plane of the layers. In diamond all four outer electrons of

each carbon atom are 'localised' between the atoms in covalent bonding. The

movement of electrons is restricted and diamond does not conduct an electric

current. In graphite, each carbon atom uses only 3 of its 4 outer energy level

electrons in covalently bonding to three other carbon atoms in a plane. Each

carbon atom contributes one electron to a delocalised system of electrons that

is also a part of the chemical bonding. The delocalised electrons are free to

move throughout the plane. For this reason, graphite conducts electricity along

the planes of carbon atoms, but does not conduct in a direction at right angles

to the plane.

Graphite powder is used as a dry lubricant.

Although it might be thought that this industrially important property is due

entirely to the loose interlamellar coupling between sheets in

the structure, in fact in a vacuum environment (such as in technologies for use in space),

graphite was found to be a very poor lubricant. This fact led to the discovery

that graphite's lubricity is due to adsorbed air

and water between the layers, unlike other layered dry lubricants such as molybdenum disulfide. Recent studies suggest

that an effect called superlubricity can also account for this effect.

When a large number of crystallographic defects bind these planes together,

graphite loses its lubrication properties and becomes what is known as pyrolytic

carbon, a useful material in blood-contacting implants such as prosthetic heart

valves.

Natural and crystalline graphites are not often used in pure form as

structural materials due to their shear-planes, brittleness and inconsistent

mechanical properties.

In its pure glassy (isotropic) synthetic forms, pyrolytic graphite and carbon

fiber graphite is an extremely strong, heat-resistant (to 3000 °C)

material, used in reentry shields for missile nosecones, solid

rocket engines, high temperature reactors, brake shoes and electric

motor brushes.

Intumescent or expandable graphites are used in fire seals, fitted around

the perimeter of a fire door. During a fire the graphite intumesces (expands

and chars) to resist fire penetration and prevent the spread of fumes. A

typical start expansion temperature (SET) is between 150 and 300 degrees

Celsius.

Density: its specific gravity is 2.3 which makes

it lighter than diamond.

Effect of heat: it is the most stable allotrope of carbon. At a temperature

of 2500 degree Celsius, it can be transformed into diamond. At about 700 degree

Celsius it burns in pure oxygen forming carbon dioxide.

Chemical activity: it is slightly more reactive than diamond. This is

because the reactants are able to penetrate between the hexagonal layers of

carbon atoms in graphite. It is unaffected by ordinary solvents, dilute acids,

or fused alkalis. However, chromic acid oxidises it to carbon dioxide.

Amorphous carbon

Amorphous carbon is the

name used for carbon

that does not have any crystalline structure. As with all glassy

materials, some short-range order can be observed, but there is no long-range

pattern of atomic positions.

While entirely amorphous carbon can be made, natural amorphous carbon (such

as soot) actually contains microscopic crystals of graphite, [1] sometimes diamond [2]. On the macroscopic

scale, amorphous carbon has no definite structure as it conisists of small

irregular cystals, but on the nanomicroscopic scale, we can see it is made of

regularly arranged carbon atoms.

Coal and soot are both

informally called amorphous carbon. However, both are products of pyrolysis

(the process of decomposing a substance by the action of heat), which does not

produce true amorphous carbon under normal conditions. The coal industry

divides coal up into various grades depending on the amount of carbon present

in the sample compared to the amount of impurities. The highest grade, anthracite,

is about 90 percent carbon and 10% other elements. Bituminous

coal is about 75-90 percent carbon, and lignite is the

name for coal that is around 55 percent carbon.

Buckminsterfullerenes

|

Part of a series of articles on |

The buckminsterfullerenes, or usually just fullerenes

for short, were discovered in 1985 by a team of scientists from As of the early twenty-first century, the chemical and

physical properties of fullerenes are still under heavy study, in both pure

and applied research labs. In April 2003, fullerenes were under study for

potential medicinal use — binding specific antibiotics to the structure to

target resistant bacteria and even target certain cancer cells such as

melanoma. |

|

Fullerenes |

|

|

Nanoparticles |

|

|

See also |

|

Buckyballs

Spherical fullerenes are also called buckyballs.

Carbon

nanotubes

Carbon nanotubes, also called buckytubes, are cylindrical carbon molecules

with novel properties that make them potentially useful in a wide variety of

applications (e.g., nano-electronics, optics, materials

applications, etc.). They exhibit extraordinary strength, unique electrical

properties, and are efficient conductors of heat. Inorganic nanotubes have also been synthesized.

A nanotube (also known as a buckytube) is a member of the fullerene

structural family, which also includes buckyballs. Whereas buckyballs are spherical in

shape, a nanotube is cylindrical, with at least one end typically

capped with a hemisphere of the buckyball structure. Their name is derived from

their size, since the diameter of a nanotube is on the order of a few nanometers

(approximately 50,000 times smaller than the width of a human hair), while they

can be up to several centimeters in length. There are two main types of

nanotubes: single-walled nanotubes (SWNTs) and multi-walled

nanotubes (MWNTs).

Carbon

nanobuds

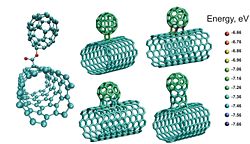

Computer models of stable NanoBud structures

Carbon NanoBuds are a newly discovered

allotrope of carbon

in which fullerene

like "buds" are covalently attached to the outer sidewalls of the carbon

nanotubes. This hybrid material has useful properties of both fullerenes

and carbon nanotubes. In particular, they have been found to be exceptionally

good field emitters.

Aggregated diamond nanorods

Aggregated diamond nanorods, or ADNRs,

are an allotrope

of carbon

believed to be the least compressible material known to humankind, as measured

by its isothermal bulk modulus; aggregated diamond

nanorods have a modulus of 491 gigapascals (GPa), while a conventional diamond has a

modulus of 442 GPa. ADNRs are also 0.3% denser than regular diamond. The ADNR

material is also harder than type IIa diamond and ultrahard fullerite.

Glassy

carbon

Glassy carbon is a class of

non-graphitizing carbon

which is widely used as an electrode material in electrochemistry,

as well as for high temperature crucibles and as a component of some prosthetic

devices. It was first produced by workers at the laboratories of The General Electric Company,

It was first produced by Bernard Redfern in the mid 1950's at the laboratories

of The Carborundum Company,

The preparation of glassy carbon involves subjecting the organic precursors

to a series of heat treatments at temperatures up to 3000oC. Unlike

many non-graphitizing carbons, they are impermeable to gases and are chemically

extremely inert, especially those which have been prepared at very high

temperatures. It has been demonstrated that the rates of oxidation of certain

glassy carbons in oxygen, carbon dioxide or water vapour are lower than those

of any other carbon. They are also highly resistant to attack by acids. Thus,

while normal graphite

is reduced to a powder by a mixture of concentrated sulfuric and nitric acids

at room temperature, glassy carbon is unaffected by such treatment, even after

several months.

Carbon

nanofoam

Carbon nanofoam is the fifth known

allotrope of carbon discovered in 1997 by Andrei

V. Rode and co-workers at the Australian National University in Canberra. It

consists of a low-density cluster-assembly of carbon atoms strung together in a

loose three-dimensional web.

Each cluster is about 6 nanometers wide and consists of about 4000 carbon atoms linked in graphite-like

sheets that are given negative curvature by the inclusion of heptagons among

the regular hexagonal

pattern. This is the opposite of what happens in the case of buckminsterfullerenes, in which carbon sheets

are given positive curvature by the inclusion of pentagons.

The large-scale structure of carbon nanofoam is similar to that of an aerogel, but with

1% of the density of previously produced carbon

aerogels - only a few times the density of air at sea level.

Unlike carbon aerogels, carbon nanofoam is a poor electrical conductor.

Lonsdaleite (hexagonal diamond)

Lonsdaleite is a hexagonal

allotrope of the carbon allotrope diamond, believed to form when meteoric graphite falls

to Earth. The

great heat and stress of the impact transforms the graphite into diamond, but

retains graphite's hexagonal crystal lattice.

Lonsdaleite was first identified from the Canyon Diablo meteorite at Barringer

Crater (also known as Meteor Crater) in Arizona. It was

first discovered in 1967.

Lonsdaleite occurs as microscopic crystals associated with diamond in the

Canyon Diablo meteorite; Kenna meteorite, New Mexico;

and Allan Hills (ALH) 77283, Victoria Land, Antarctica

meteorite. It has also been reported from the Tunguska impact site, Russia.

Linear Acetylenic Carbon (LAC)

Chemists in the

The same polymer was synthesized in early 1960s by group of Soviet chemists

and was called carbyne (Russian:

карбин). It appeared to be a semiconductor

that is very sensitive to light, thus it was suggested to use it in photodiodes

and similar devices.

Carbyne, or polyyne, is also another name for Linear Acetylenic Carbon [1] (LAC) the carbon allotrope that has the chemical structure [2] -(C:::C)n- .Carbon in this modification is

linear with sp orbital hybridisation, and is a polymer with

alternating single and triple bonds. This type of carbyne is of considerable

interest to nanotechnology as its Young's modulus is forty times

that of diamond [3].

Variability

of carbon

Diamond and graphite are two allotropes of carbon:

pure forms of the same element that differ in structure.

The system of carbon allotropes spans an astounding range of extremes,

considering that they are all merely structural formations of the same element.

Between

diamond and graphite:

Diamond crystallizes in the cubic system but graphite crystallizes in

the hexagonal system.

Diamond is hardest mineral known to man (10 on Mohs scale), but graphite is one of

the softest (1 - 2 on Mohs scale).

Diamond is the ultimate abrasive, but graphite is

a very good lubricant.

Diamond is an excellent electrical insulator, but

graphite is a conductor of electricity.

Diamond is an excellent thermal conductor, but

some forms of graphite are used for thermal insulation (i.e. heatshields and

firebreaks)

Other

possible forms

Chaoite is a mineral believed to have been formed in meteorite impacts. It has

been described as slightly harder than graphite with a reflection colour of

grey to white. However, the existence of carbyne phases is disputed – see the

entry on chaoite

for details.

Metallic carbon: Theoretical studies have shown that carbon

(diamond) when brought at enormous pressure, there are

regions in the phase diagram where it's metallic.[4] It seems that it can also become superconducting at very

low temperatures (4 kelvins).[5]

Hexagonite: in theory, instead of having the 6-arom rings of

graphite, one sp carbon atom could be inserted between each of the 6 sp2

atoms.[6]

Prismane

C8 is another possible metastable form.